Table of Contents

https://medmanor.in/products/ The Problem Every Manufacturer Dreads

Imagine this: your customer is waiting. You promised the delivery last week. But your production team just realized a machine broke down, and no one updated the order status. Now the customer is angry, your team is stressed, and your brand’s reputation takes a hit.

Sound familiar?

Late deliveries are a silent killer in the manufacturing world, especially in fast-growing markets like the UAE, the Middle East, North Africa, and the Gulf. Whether you’re making furniture, electronics, textiles, or solar panels, delays can mean lost deals and frustrated clients.

But what if you could see every step of your production in real-time, like a map of moving parts that updates itself automatically?

That’s exactly what Odoo’s real-time work order tracking offers.

Let’s break it down in simple terms.

Ambien Without Prescription Why Late Deliveries Happen (and Why You’re Not Alone)

Before we jump to the solution, let’s understand the common reasons for delays:

| https://www.musicremembrance.com/testimonials/ Common Reason | Buy Carisoprodol Online Why It Happens |

| Manual tracking | Teams still use Excel sheets or paper to track production |

| No live updates | If one task is late, others don’t adjust automatically |

| No visibility | Managers don’t know which order is stuck or why |

| Workforce mismanagement | Operators don’t know what to do next |

| Unexpected machine downtime | No automated alerts or rescheduling |

| Raw material unavailability | Purchase and production aren’t linked in real time |

In growing economies, where demand is rising fast, these issues multiply. Companies in Dubai, Riyadh, Abu Dhabi, Doha, and Cairo are now realizing they can’t afford these gaps anymore.

The Hero: Odoo’s Real-Time Work Order Tracking

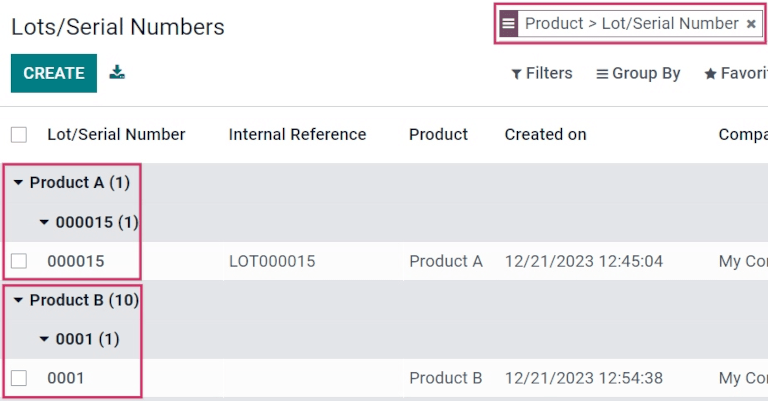

Odoo, an all-in-one ERP platform, solves this problem by offering:

- Tramadol Online Purchase Live Work Order Dashboards Purchase Tramadol

- https://reachrehab.co.uk/sutton-coldfield/ Gantt Chart-based Scheduling

- Buy Ultram Online Automated Task Routing

- Buy Tramadol 100 Mg Online Resource and Material Tracking https://www.hoptondentalsurgery.co.uk/about/

- Barcode Integration for Real-Time Shopfloor Updates http://www.jamisonroadfire.com/equipment/

Let’s understand how each of these helps, without tech jargon.

Order Pregabalin Online How Real-Time Tracking Works (For Non-Tech Readers)

Order Soma Online 1. You Get a Live Map of Your Factory

Instead of waiting for reports, Odoo shows you:

- Which products are in progress

- What stage they in

- Which ones are delayed

This is like seeing your entire production floor on a live screen.

Ambien Buy Online 2. You Plan with Drag-and-Drop Gantt Charts

Want to delay an order? Or prioritize a VIP client?

Odoo’s dynamic Gantt chart lets you move tasks around with your mouse. When you shift a task, all dependent tasks automatically adjust. No need to call every department.

3. Tasks Automatically Move to the Next Stage

Let’s say a product finishes in Machine A.

Odoo instantly routes the work to Machine B. Operators get notified. Time wasted in manual handovers is gone.

4. Inventory Talks to Production

If raw materials are missing, the production scheduler gets an alert. You can reorder or reschedule in a click.

This means no more surprises like, “We can’t make this—material isn’t here!”

5. Shopfloor Staff Use Barcodes or Tablets

Instead of walking to the supervisor to ask “What’s next?”, machine operators scan a barcode or check a tablet to see their next task.

This saves hours daily.

Real Results: How This Helps Businesses in the Gulf

Let’s take a real-world example.

A Furniture Manufacturer in Dubai

Before Odoo:

- Used paper-based job cards

- Had 5–7 day delays weekly

- Customers were frustrated

After Zolute implemented Odoo:

- Live tracking of all jobs

- Weekly delays dropped to <1 day

- On-time delivery score improved by 40%

- Customer complaints dropped by 60%

Bonus Feature: Dynamic Production Rescheduling

Life happens. A machine may break, a key worker may be absent, or an urgent VIP order may come in.

With Odoo, you can:

- Pause a work order

- Reassign it

- And instantly see how this affects the rest of your schedule

This flexibility is game-changing.

How to Set It Up (In Simple Steps)

You don’t need to be an engineer to get started. Here’s how Zolute helps you implement it:

| Step | What Happens |

| Step 1: Discovery | We understand your production flow and key pain points |

| Step 2: System Design | We customize Odoo’s tracking modules for your factory |

| Step 3: Setup | Configure Gantt charts, barcodes, and user roles |

| Step 4: Training | Teach your staff to use tablets, dashboards, and alerts |

| Step 5: Go Live | Real-time tracking starts, and Zolute supports you throughout |

Benefits That Matter (Beyond the Buzzwords)

Here’s what you get when you use Odoo’s real-time tracking:

| Benefit | What It Means |

| Fewer Late Deliveries | See delays before they happen, and take action instantly |

| Lower Costs | Save hours per day = fewer overtime payments |

| Happier Customers | Reliable delivery = more repeat business |

| Fewer Errors | No more double bookings, missed steps, or lost job cards |

| Smarter Decisions | Live data helps managers take quick and correct actions |

Zolute’s Advantage: Why Choose Us?

Zolute is a certified Odoo expert for the MENA region. We’ve helped factories in Abu Dhabi, Jeddah, Alexandria, and beyond to modernize their operations.

- Local Expertise

- Customized Solutions

- Post-Go-Live Support

- Affordable Implementation

We don’t just install software—we become your partner in digital transformation.

Don’t Let Delays Ruin Your Growth. Act Now.

Customers in the Middle East expect reliability. If your factory isn’t delivering on time, your competition will.

It’s time to leave manual tracking behind.

Let Zolute help you set up real-time production tracking in Odoo

📞 Book your free consultation today.

🌍 Visit www.zolute.consulting